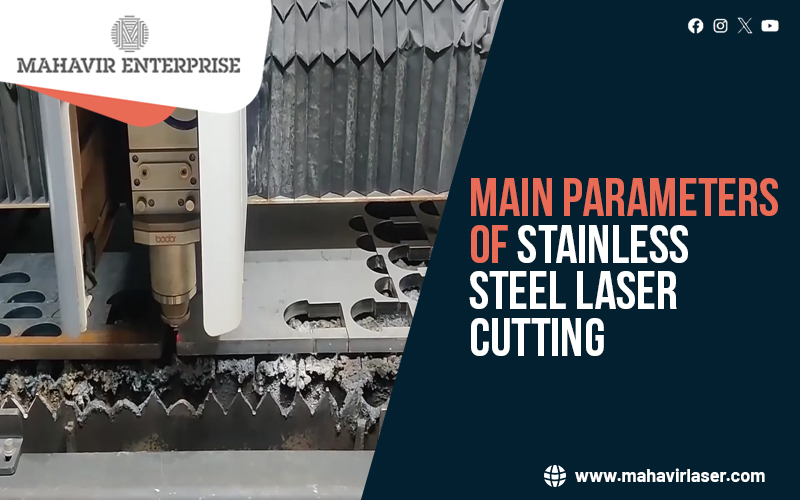

Laser cutting is a state-of-the-art cutting method that has changed material cutting. It is widely used to cut steel in industrial manufacturing processes for its excellent efficiency, accurate results, cost-effectiveness, and workability with different thicknesses. Optimizing laser cutting parameters for stainless steel is crucial for a precise, clean, and detailed cut. In this blog, we share tips on how to improve your laser cutting process for stainless steel.

Main Parameters of Stainless Steel Laser Cutting to Follow

Power of Laser Beam

Laser power is an important parameter to consider in laser cutting stainless steel. This determines the power and intensity of the laser beam and its ability to melt and vapourize stainless steel. High power lasers lead to faster & more precise cutting speeds. However, undesired high-cutting power can also result in excessive heat and material deformation. It is crucial to find the right balance to achieve precise and clean cuts.

Cutting Speed

The cutting speed in laser cutting is the pace at which the laser beam moves, directly influencing the quality and efficiency of the cut. To optimize SS laser cutting speed, consider the stainless steel grade and thickness, ensuring precise and detailed cutting. Slow cutting allows for more heat absorption for smoother and cleaner cuts. However, relatively slow cutting can result in high heat build-up and material deformation.

Gas Selection

Selecting an appropriate assist gas is another parameter of stainless steel laser cutting. The gas helps to blow away any molten material and prevent oxidization. Oxygen and nitrogen are some of the most commonly used assist gasses for stainless steel gases.

Diameter Nozzle

The diameter of the nozzle is an essential component in the laser cutting process. This impacts the concentration and focus of the laser beam, which affects the cutting quality. A small nozzle diameter allows a more focused beam for a narrower kerf and better accuracy. However, a smaller nozzle also implies a slower cutting speed. It is crucial to find the right balance between accuracy and cutting speed for SS laser cutting, which can be done by choosing the right nozzle diameter.

Laser cutting is an advanced technology capable of processing a wide range of materials in intricate shapes and patterns. Mahavir Enterprise is the top laser cutting company Vadodara. We provide top-notch laser cutting services for mild steel, stainless steel, aluminium, copper, and brass. Contact us to discuss your project requirements.