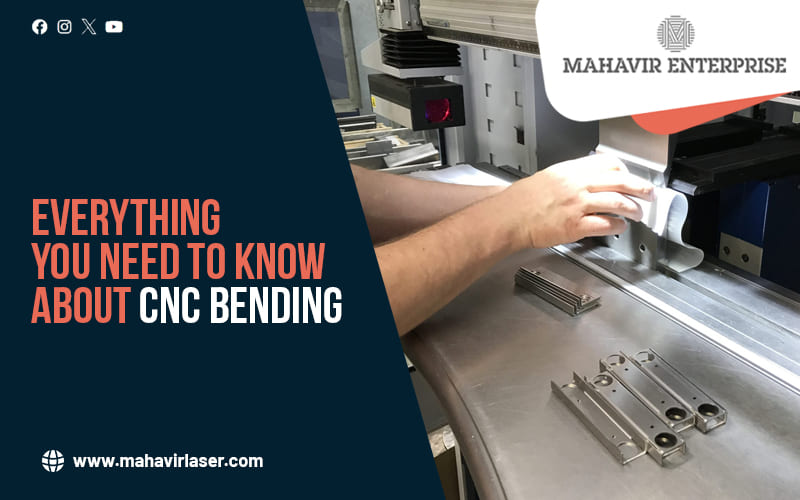

The CNC bending technology has taken over the traditional manual bending of metal tubes and sheets. These processes and machinery have made bending and fabrication more efficient and accurate. In this blog, we have a closer look at the CNC bending process and highlight its role in metal fabrications.

What is CNC Bending?

Computer Numerically Controlled (CNC) bending is a commonly used fabrication technique for forming sheet metal and tubes. This process is done by CNC press brakes that can bend metal sheets from a few millimetres across to multiple meters long. CNC sheet metal bending is done consistently and with precise dimensions using an automated process.

Key Characteristics of CNC Metal Bending

- Automated Process

CNC machines are fully automated, allowing for precise and consistent bending. A computer controls the machine and hydraulic system to deliver precision components with exact dimensions.

- Compatible Metal with Right Machine

These machines are versatile handling metal sheets and tubes from a few mm to many meters long. However, when it comes to CNC bending services, the size of the machine and the strength of the metal, in case an incompatible metal is paired with the wrong machine, can lead to breakage or overbending.

- Tensile Strength

CNC bending machines are capable of producing intricate, complex components due to sophisticated technology.

How Does CNC Metal Bending Work?

CNC metal bending is an advanced fabrication process that uses computer-controlled machines to manipulate material into precise shapes and angles. Below is a brief explanation of how CNC bending works:

- Design & Programming: The process begins with a design created in CAD specifying dimensions, angles and other details needed in the end product. The design is converted to a set of instructions for the machine. The system calculates the most efficient bending sequence, force and angles needed for every bend.

- Material Selection & Preparation: Before starting the bending process, it is crucial to select the right material and thickness for the needs of the project. Some common materials used are aluminium, stainless steel, mild steel, etc.

- The Bending Process: The CNC press brake is set with the right tools and dies as the metal types and thickness and the required bend angles. The metal is placed on the CNC press brake machine’s bed against the back gauges to ensure proper alignment for the bend. After the metal is placed, the machine’s upper beam fitted with a punch lowers and presses the metal into the die to create a precise bend angle.

- Quality Control: After the metal bending, the material undergoes a rigorous quality control process. It is evaluated for precision to ensure it matches the design specifications. Any adjustments needed are done at this stage, ensuring that the final product meets the highest standards of quality and precision.

CNC metal bending has changed the metal fabrication industry, allowing for the production of complex and high-precision components. Mahavir Enterprise offers CNC bending in Vadodara tailored to fit your material processing requirements. To discuss your CNC bending requirements, call us.